Understanding Mica Band Heaters and Their Industrial Applications

- Heat Tech Systems

- Jul 25, 2025

- 4 min read

Mica band heaters are pivotal elements across many industrial sectors, valued for their efficiency and versatility. These heating devices excel at heating circular surfaces through conduction, making them essential for a variety of manufacturing processes. If you're curious about mica band heaters, their features, benefits, and uses, you've come to the right place to learn more.

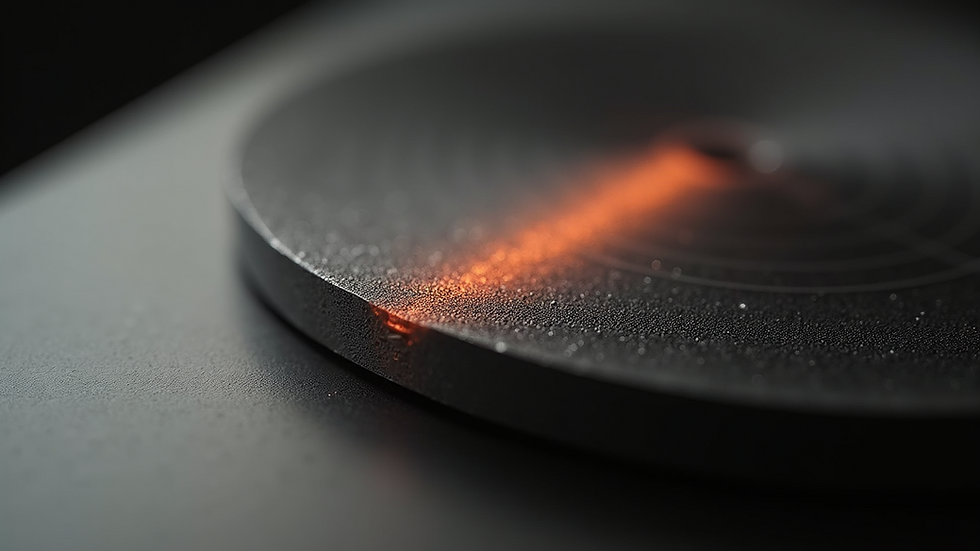

What is a Mica Band Heater?

Mica band heaters are ring-shaped electrical heating devices designed to encircle cylindrical objects. Typically constructed with mica insulation, these heaters utilize metal filaments that convert electricity into heat.

When installed, a mica band heater wraps around the outer surface of a cylinder, enabling efficient heat transfer primarily by conduction. In some cases, these heaters can also clamp internally, allowing for different heating applications.

The construction quality of mica band heaters minimizes heat loss due to the mineral and ceramic insulation used. This not only saves energy but also enhances the heater's performance by maintaining consistent operational temperatures.

How Do Heating Bands Work?

Heating bands operate through a simple mechanism. When electric current passes through the metal filament, it generates heat. This heat is then transferred to the object the heater encircles.

Conduction and Convection

Two primary methods of heat transfer at play are conduction and convection:

Conduction: This occurs when the band heater is in direct contact with the object, effectively transmitting heat to its surface. Studies indicate that good contact can improve energy transfer by up to 30%.

Convection: Heat can also be emitted into the surrounding air, which then warms the object without direct contact. While less efficient than conduction, convection is helpful in applications requiring gradual heat distribution.

Mica band heaters are especially popular in the plastics industry. For instance, they are vital in heating molds during processes such as extrusion and injection molding, where precise temperature control is crucial.

Benefits of Mica Band Heaters

Mica band heaters provide various advantages that make them appealing for heating applications:

Temperature Control: These heaters are effective in environments needing regulated lower maximum temperatures. For example, maintaining 180°F to 250°F in plastics processing minimizes warping.

Corrosion Resistance: Mica boasts high corrosion resistance, making heaters suitable for industries exposed to chemicals, such as food processing and pharmaceutical manufacturing.

Dielectric Strength: With high dielectric strength, mica band heaters can be tailored for various electrical configurations, offering flexibility in a range of applications.

Chemical and Water Resistance: These heaters can handle strong chemicals and moisture, making them reliable even in hazardous environments.

Flexibility: Slight bending capabilities enable mica band heaters to conform to various surfaces without sacrificing efficiency.

Energy Efficiency: Efficient insulation minimizes heat loss, leading to energy savings of approximately 20% or more over time in well-insulated systems.

Collectively, these benefits make mica band heaters an excellent choice for many industrial uses.

Applications of Mica Band Heaters

Mica band heaters are employed in several sectors, thanks to their adaptability and efficiency. Notable applications include:

Plastics Industry

In the plastics sector, mica band heaters are utilized to heat molds effectively. The ability to maintain a specific temperature is vital for processes like injection molding, where even a small deviation in temperature can impact the final product. For example, a consistent temperature of 350°F is often required for certain thermoplastics to ensure perfect molding.

Food Processing

Mica band heaters are used in food processing to properly heat and maintain temperatures for cooking or treating food products. They help achieve consistent heating, which is crucial for food safety. An example is using these heaters for maintaining cooking temperatures between 140°F to 180°F in commercial kitchens.

Pharmaceutical Industry

In pharmaceutical production, precise temperature regulation is essential to prevent contamination and preserve sensitive compounds. For instance, maintaining a stable temperature around 120°F can enhance the quality of certain compounds during processing.

Packaging Industry

In packaging, mica band heaters are regularly employed in operations like shrink-wrapping and sealing. Their ability to generate the necessary heat for film shrinking ensures product integrity and enhances presentation.

Chemical Processing

Consistency is critical in the chemical sector. Mica band heaters are used to heat reactors to maintain the required temperature for chemical reactions, improving processing efficiency. For example, stabilizing temperature in reactors can increase yield by up to 15%.

Choosing the Right Mica Band Heater

Selecting the appropriate mica band heater for an application involves several key factors:

Size and Configuration

Choose a mica band heater that fits snugly around the cylindrical object. Proper sizing guarantees optimal heat transfer and reduces energy waste, leading to better operational efficiency.

Maximum Temperature Rating

Different applications have unique temperature needs. Select a heater that aligns with the specific maximum temperature requirements to ensure safe and effective operation.

Watt Density

The watt density indicates power output per square inch. An appropriate watt density ensures quicker and more efficient heating, improving how effectively heat is delivered to the object.

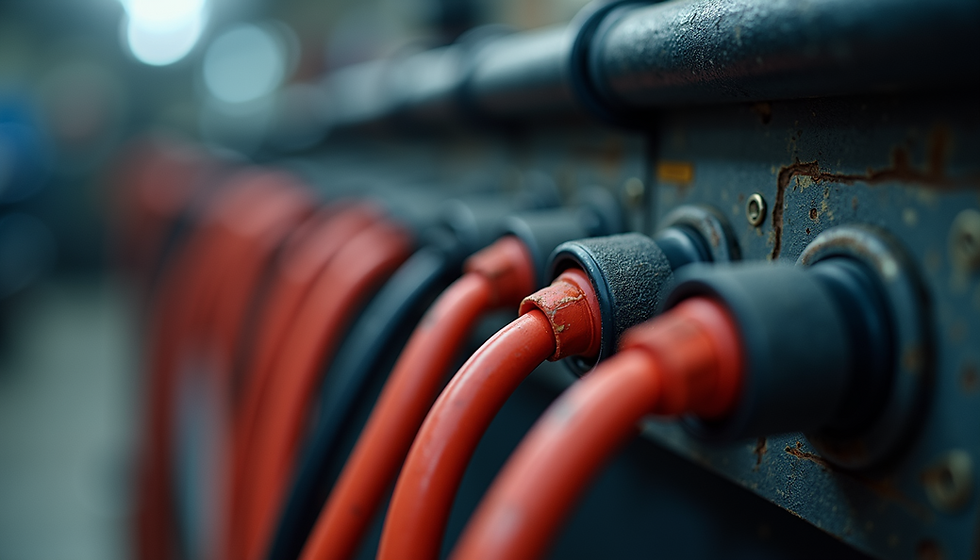

Voltage and Power Supply Compatibility

Ensure the mica band heater matches your facility's existing power supply. Compatibility is vital for seamless integration, thus enhancing operational efficiency.

Maintenance and Safety Tips

While mica band heaters are reliable, regular maintenance and safety protocols are crucial for optimal performance:

Regular Inspection

Inspect the mica band heater frequently to ensure proper functioning. Look out for signs of wear, damage, or irregular operation to prevent breakdowns.

Cleanliness

Keep the heater free from dust and debris. Accumulation can reduce efficiency, leading to overheating or even short circuits.

Avoid Overheating

Constantly monitor the operating temperature to avoid exceeding maximum limits. Overheating can shorten the heater's lifespan and damage nearby equipment.

Professional Installation

Consider hiring professionals for installation to ensure the heater fits and functions correctly. Incorrect installation can cause inefficiencies and safety risks.

Final Thoughts

Mica band heaters serve as invaluable assets across various industrial applications, offering effective and controlled heating solutions. Their construction and benefits make them ideal for environments requiring precise temperature management and durability against harsh conditions.

As industries evolve and demand more efficient heating technologies, mica band heaters distinguish themselves as reliable solutions that enhance productivity and operational performance. A proper understanding of their functionality and applications empowers industries to choose the right heating technology, ensuring safety and efficiency in their processes.

Comments